Geotechnical engineering research

Geomechanics of Mine Waste Management

Over more than 30 years, Professor David Williams has been at the forefront of the application of geotechnical engineering principles to mine waste management, mine design, mineral processing, and mine closure.

Our Projects

- The characterisation of the deposit formed on the pumped co-disposal of combined washery wastes, which has since been adopted at numerous coal mines in Australia and Indonesia.

- Development of the store and release cover system suited to seasonally dry climates, for application to covering acid generating waste rock dumps. The store and release cover system on the tops of the Kidston rock dumps has been shown to limit net percolation to less than 1% of average annual rainfall, and to support a sustainable vegetation cover comparable to that occurring along water courses in the area. Store and release covers have now been adopted at numerous mine sites in dry climates in Australia and worldwide.

- Development of a risk assessment and cost-effectiveness analysis for the rehabilitation of Bowen Basin coal mine spoil, in the form of a spreadsheet-based tool.

- Closure design for waste rock dumps at Cadia Hill Gold Mine in New South Wales, including an instrumented 0.7 ha, 15 m high trial waste rock dump, and studies on the use of mixtures of benign trafficked rock and tailings as an alternative cover material, to overcome the shortage of suitable natural materials. The majority of the infiltration went into storage within the dump during the first year, and only small amounts percolated to the base of the dump over time.

- Assessment of the long-term seepage and runoff from hypersaline mine tailings storage facilities in an arid climate, to facilitate lease surrender. This included the monitoring of trial covers on tailings over the duration of the project and large-scale laboratory column testing and numerical analyses, compared with natural analogues.

- Investigating the settlement and stability of high coal mine spoil, and the behaviour of problematic clay mineral-rich coal mine tailings.

Geomaterial Modelling and Computational Geomechanics

Geomaterials are a highly complex mixture of solid particles, pore water and pore air, requiring the development of innovative, complex mathematics and algorithms, and the use of parallel computing, which the former Geotechnical Engineering Centre developed.

In addition to conventional methods (e.g. finite element methods, FEM), the Centre extends and develops new methods for the prediction of the mechanical behaviour of (porous) solids and granular materials, including (where desired) multi-component fluid flow. Continuum and discrete approaches are both considered.

Our Projects

Dr Dorival Pedroso, and his co-workers, developed the computer software MechSys (Open Library for Mechanical Systems), which serves as a basis for the development of the models and solvers. MechSys includes FEM, and in collaboration with Dr Sergio Galindo-Torres has added the discrete element method (DEM), smoothed-particle hydrodynamics (SPH), and the lattice Boltzmann method (LBM). MechSys is under constant development.

Another focus is engineering optimisation, in particular employing advanced new optimisation techniques such as Genetic Algorithms. For this, the computer library SGA (Simple Genetic Algorithms) serves as a basis for the development of optimisation tools. Accuracy and reliability are of key importance.

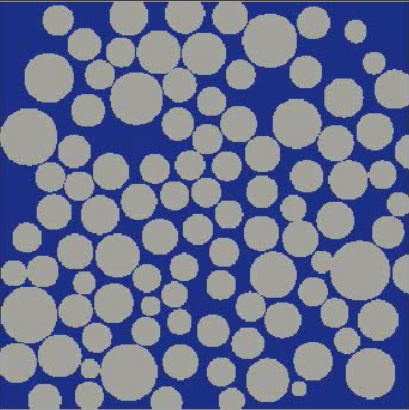

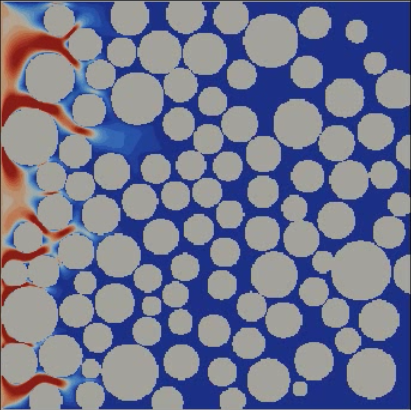

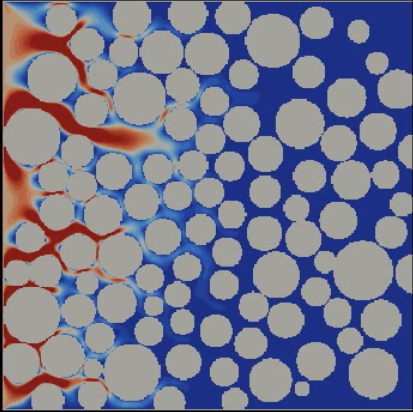

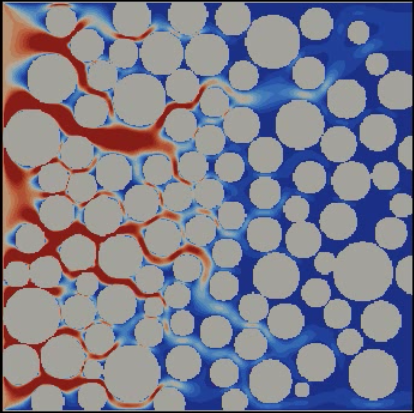

MechSys/LBM modelling of flow through porous media

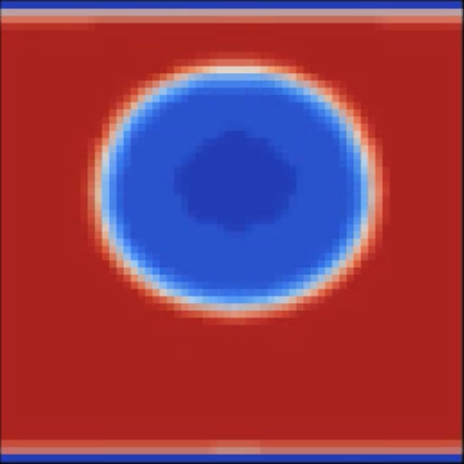

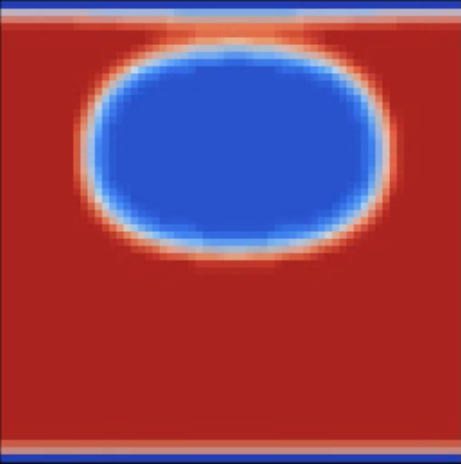

MechSys/LBM simulation of viscous fluid flow under gravity around an obstacle

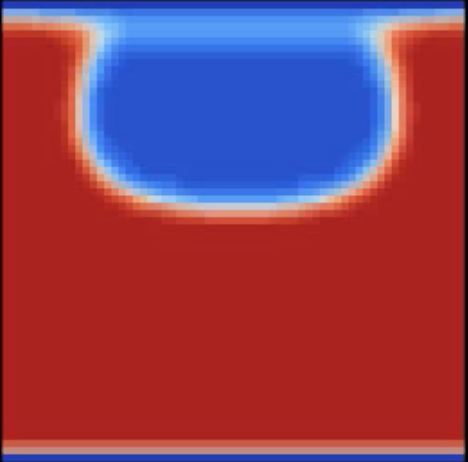

MechSys/LBM simulation of multi-component flow – a bubble (shown in blue) expands, moves to the surface, then breaks the surface, while the liquid (shown in red) settles

Advanced Laboratory and Field Characterisation

The advanced laboratory and field characterisation and testing, modelling, and monitoring of slurries, soils and rocks has been a focus of the Centre’s research, involving many of its researchers.

Laboratory testing has included the sedimentation testing of tailings slurries, the consolidation testing of soft soils and tailings through to coal mine spoil under stresses of up to 10 MPa, the shear strength testing of soft soils and tailings through to coal mine spoil, and the soil water characteristic and saturated hydraulic conductivity testing of soils and spoil. Soil and tailings slurries have been subjected to laboratory modelling to determine their beaching behaviour and their consolidation under load.

Our Projects

Laboratory testing projects have included desiccation of clay liners, column testing of mine tailings, filtration testing of tailings, and the application of an ultra-high speed camera to capturing rock fracture.

Field testing and monitoring has included the instrumentation of tailings and mine waste covers, pile load testing, the application of ground penetrating radar, and hydraulic conductivity and density testing of fine and coarse-grained mine wastes.

(above) Ultra-high speed camera for capturing rock fracture

(above) Ground penetrating radar testing of mine haul roads

Geo-environmental Engineering and Geophysical Methods

Dr Alexander Scheuermann is an expert in dam engineering, geo-environmental engineering and flood protection.

He has also researched the hydraulics and mechanics of unsaturated soils. His research activities include hydro-mechanically coupled processes such as erosion, shrinkage of soils, stability of partly-saturated soils and hydraulic fracturing; and transient seepage, infiltration of water, soil water retention curve and preferential flow of water. To investigate these processes, he uses geophysical methods such as Time Domain Reflectometry (TDR), Electrical Resistivity Tomography, Ground Penetrating Radar and Dielectric Spectroscopy.

For almost 15 years, Alexander has been working on the development, modification and application of spatial TDR for observing geo-environmental and geotechnical processes and co-developed a method called Spatial TDR. The advantage of Spatial TDR compared to conventional TDR methods is its ability to determine profiles of desired parameters such as the volumetric water content. Applications of this novel technology include the observation of water content changes within embankments, in small catchments for improving flood forecasting or in mine waste cover systems. Further applications include the determination of soil water characteristics, the measurement of porosity changes during erosion, and potentially fluidisation and the measurement of stress changes.

Management of Large Open Pit Project (LOP II)

Professor David Williams, assisted by Dr Mehdi Serati, manages the industry-funded Large Open Pit Project (LOP II, 2016-2019), a continuation of LOP I (2004-2015), and is managing the funding of LOP III (2019-2022).

The focus of LOP I was the development and publication of a number of guidelines including Guidelines for Open Pit Slope Design (Read and Stacey, 2007), Guidelines for Evaluating Water in Pit Slope Stability (Beal and Read, 2013), and the soon to be published Open Pit Dewatering, Guidelines for the Design of Slopes in Weak Rock, and Guidelines for the Design of Mine waste Dumps and Stockpiles. LOP II will continue the tradition of setting standards for the industry and improving on the state-of-the-art through targeted research with short-term deliverables.

The focus of LOP II is data and design uncertainty, accounting for blast-induced rock damage, drafting Guidelines for Slope Monitoring, laser scanning and structural modelling, updating design acceptance criteria, developing an LOP Website (www.lopproject.com), and effective stresses in large open pit slopes.

Themes for LOP III – Open Pit of the Future include automation of mining and its implications for the factor of safety and the resource; data acquisition and visualisation; data management and analytics; open pit closure, including in-pit tailings and pit lakes; monitoring, risk management and artificial intelligence; staffing and capability; mining methods; mine void design; dynamic slope stability; implications of deeper open pits; and interaction and transition between ongoing open pit and underground.

Current and Recent Projects

- Mine tailings water cycle and mine waste cover systems

- Effectiveness of liners for water storage ponds

- Settlement of high coal mine spoil

- Flow in coal seams

- Behaviour of screw auger piles in clay

- Problematic clay mineral-rich coal mine tailings

- Computational geomechanics, including FEM (MechSys), DEM and LBM:

- Rock fracture, damage and cutting

- GPR applied to tunnelling

- Erosion of granular structures

- Development and application of spatial TDR

- Hydraulic fracturing

- Application of geophysical methods to geo-environmental and geotechnical engineering

Researchers Take on Ever-increasing Waste Glass and Overexploitation of Natural Sand

Description of the Video Abstract:

The video abstract features Danish Kazmi, a PhD candidate, and his PhD advisors Professor David Williams and Dr Mehdi Serati. It presents the key motivations, analyses performed, and conclusions of cross-institutional research published recently in the Journal of Cleaner Production, a Q1 journal ranked number# 1 worldwide in Sustainable Development at the time of this article publication.

Performed in collaboration with University College London (UK) and other external organisations, this research investigated the potential use of ever-increasing waste glass as a sustainable alternative to depleting natural and manufactured sand in geotechnical construction. The study compared the geotechnical, mineralogical and morphological behaviour of crushed waste glass with that of two traditional types of construction sand. The findings showed that the geotechnical behaviour of crushed waste glass is similar, or sometimes even superior, to traditional construction sands. Overall, it was concluded that crushed waste glass could potentially serve as an alternative and smart geomaterial, ultimately promoting the recycling of waste glass, reducing the burden on landfill and conserving natural resources, all helping the transition towards a circular economy.

Article title: The potential use of crushed waste glass as a sustainable alternative to natural and manufactured sand in geotechnical applications.

Article DOI: https://doi.org/10.1016/j.jclepro.2020.124762

Researchers Explore the Potential Use of Crushed Waste Glass as a Sustainable Geomaterial to Backfill Granular Columns

Description of the Video Abstract:

The UQ Experts in this video abstract present the key motivations, analyses performed, and findings of a cross-institutional study comparing the behaviour of a weak soil reinforced with granular columns containing three different types of backfill materials. The study conducted shear strength testing using an advanced high-accuracy large direct shear machine.

Performed in collaboration with University College London and Imperial College London in the UK, this study presents the shear strength performance of a weak soil reinforced with a crushed waste glass column and compared it with that containing a natural or quarried (manufactured) sand column.

The article reveals new insights into the unexplored shear strength performance of crushed waste glass as backfill in a granular column. Another standalone contribution of this study is that it provides an insight into how the origin of sand could impact its shear strength behaviour in granular column-reinforced soil, as natural and manufactured sands are largely sourced from beaches or rivers and quarries, respectively.

In conclusion, the study found that crushed waste glass showed promising behaviour as an alternative geomaterial and could potentially be used to backfill granular columns, helping to offer a circular economy solution by reducing pressure on landfills, recycling growing waste glass stockpiles, and conserving depleting natural and quarried sand resources.

Article title: Kaolin Clay Reinforced with a Granular Column Containing Crushed Waste Glass or Traditional Construction Sands

Article DOI: https://doi.org/10.1061/(ASCE)GM.1943-5622.0002322

UQ Experts reveal new findings on using crushed waste glass for ground improvement in construction via leading cross-institutional research

This internationally-partnered Video Abstract highlights the findings of cross-institutional research investigating the use of crushed waste glass (CWG) as a sustainable alternative to diminishing natural sands in backfilling granular columns for ground improvement in geotechnical construction, potentially supporting the transition to a circular economy and contributing to the decarbonisation of the construction industry.

The Video Abstract features researchers from The University of Queensland (UQ) in Australia and University College London (UCL) in the UK. The featured UQ Experts include Professor David Williams, Dr Mehdi Serati and Dr Danish Kazmi, alongside Dr Helen Cheng from the University College London.

Article title: Shear Strength and Consolidation Behaviour of Kaolin Clay Reinforced with a Granular Column Backfilled with Crushed Waste Glass

Article DOI: https://doi.org/10.1007/s10706-024-02748-x